Why Choose Our Air Compressor & Dryer Services

We offer comprehensive service solutions for our clients in the Nashville area. With JBS, you’ll have access to:

- Experienced technicians. Backed by the company’s century of industry expertise, our factory-trained technicians have extensive experience repairing top brands like Gardner Denver, Sullair, Ingersoll Rand, Atlas Copco, Quincy, Kaeser and more.

- Authorized service provider. JBS is an authorized Gardner Denver service provider and distributor with access to OEM components and top-notch technical support.

- 24/7 Emergency support. Equipment failures can strike at any time, bringing productivity to a halt. JBS offers 24/7 emergency services to minimize operational disruptions and get your equipment back up and running as soon as possible.

- Flexible maintenance plans. With customizable routine and preventative maintenance plans designed around your unique needs, our team will help you get the most out of your equipment. The goal is to optimize system performance and extend the service life of your air compressors and dryers.

- Comprehensive Compressed Air Capabilities. JBS offers a one-stop shop for all your compressed air needs, including audits and design, equipment sales, installation, rentals, parts and one of the only in-house airend rebuild centers in the Mid-South.

Common Air Compressor & Dryer Problems We Address

Our skilled team of industry professionals excels at diagnosing and fixing an array of issues commonly impacting air compressor and dryer equipment, including:

- Pressure drops and inefficiency. Clogged filters, air leakages, and worn or malfunctioning parts can cause air pressure to drop, decreasing system efficiency.

- Excess moisture and contamination. Moisture can build up in your system if your dryer is not performing optimally, which may result in system contamination or component corrosion. We’ll maintain your dryer and filtration system through regular industrial air dryer service.

- Overheating and system failures. Blocked coolers or filters, low oil levels, and poor ventilation lead to overheating. This ultimately harms your air compressor, and any downtime impacts productivity.

- Unusual noises and vibrations. Strange sounds or vibrations could be from parts that have worn or loosened, or from mechanical imbalances in your equipment. Finding and addressing these signs quickly is vital to keeping the root cause from worsening.

- Air and oil leaks. These leaks do more than ruin the efficiency of your equipment; they have the potential to be hazardous. Reviewing for leaks and promptly repairing connections, gaskets, and seals help support your compressor’s integrity.

Preventative Maintenance for Your Air Compressor & Dryer

Compressed air system maintenance is critical to avoiding costly downtime and ensuring your industrial equipment remains in good working order. At JBS, our personalized preventative maintenance services protect the integrity and longevity of your systems through:

- Scheduled maintenance plans. Regular inspections, detailed performance evaluations, and part replacements are common components of our customized maintenance plans. We address any potential issues proactively to support reliable, continuous operations and avoid equipment failure.

- Filter replacements and system inspections. Maintaining clean air output is a vital part of compressor and dryer performance. Clogged or compromised separators or filters can lead to damage. That’s why it’s so important to replace filters at factory-recommended maintenance intervals and conduct thorough system inspections.

- Lubrication and cooling system care. Keeping all moving parts properly lubricated minimizes friction and extends compressor and dryer life cycles. We’ll monitor oil levels, degradation, and contamination to optimize equipment performance and prevent part wear and overheating.

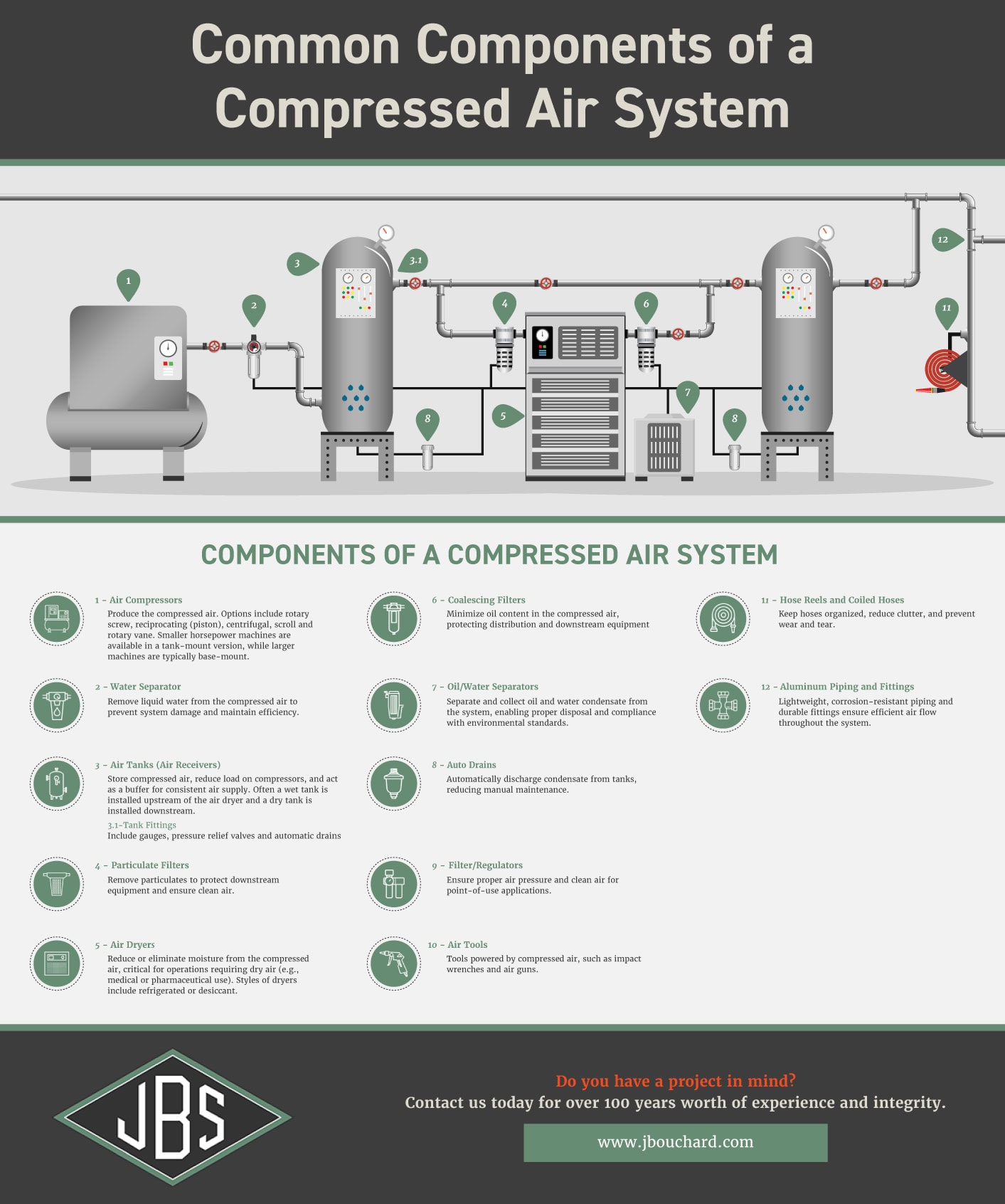

- Performance testing and air quality checks. Our technicians catch the signs of potential problems early, before they can grow into bigger, more costly challenges. We do this by regularly evaluating all components of your compressed air system including filters, oil/water separators, auto drains, dryers, tanks and others.

Middle Tennessee Service Area

Our Nashville office services the following areas regularly. If you are located elsewhere, please contact our East Tennessee, Kentucky or Southern Indiana branches.

- Clarksville (Montgomery County)

- Columbia (Maury County)

- Cookeville (Putnam County)

- Dickson (Dickson County)

- Fayetteville (Lincoln County)

- Franklin (Williamson County)

- Gallatin (Sumner County)

- Hendersonville (Sumner County)

- La Vergne (Rutherford County)

- Lawrenceburg (Lawrence County)

- Lebanon (Wilson County)

- Lewisburg (Marshall County)

- Manchester (Coffee County)

- McMinnville (Warren County)

- Mt. Juliet (Wilson County)

- Murfreesboro (Rutherford County)

- Nashville-Davidson County

- New Johnsonville (Humphreys County)

- Portland (Sumner County)

- Pulaski (Giles County)

- Shelbyville (Bedford County)

- Smithville (DeKalb County)

- Smyrna (Rutherford County)

- Springfield (Robertson County)

- Spring Hill (Maury County)

- Tullahoma (Coffee County)

Air Compressor & Dryer Repair & Service in Nashville by JBS

We offer industrial air compressor repair in Nashville, TN, to ensure our customers have well-maintained, optimally functioning equipment they can rely on. JBS takes a proactive approach to service, combining more than 100 years of experience with comprehensive air compressor and dryer capabilities to best meet our clients’ varied operational needs.

If you’re in the Middle Tennessee area searching for “air compressor repair near me,” look no further than John Bouchard & Sons. Contact us today to book a service or learn more.