Case Study: Autokiniton Compressor Install

The Challenge

John Bouchard & Sons Co., a leading provider of industrial compressed air equipment, was approached by Autokiniton Lebanon—a stamping and weld assembly provider. The client needed an upgrade to their compressed air system to meet increasing operational demands. Their existing setup, consisting of three 200 HP compressors and two 30 HP compressors, struggled to keep pace with production needs. Autokiniton had to operate all compressors simultaneously to provide sufficient airflow to the facility.

The company turned to John Bouchard & Sons looking for a reliable compressor solution to power their operations more efficiently without compromising safety.

The Solution

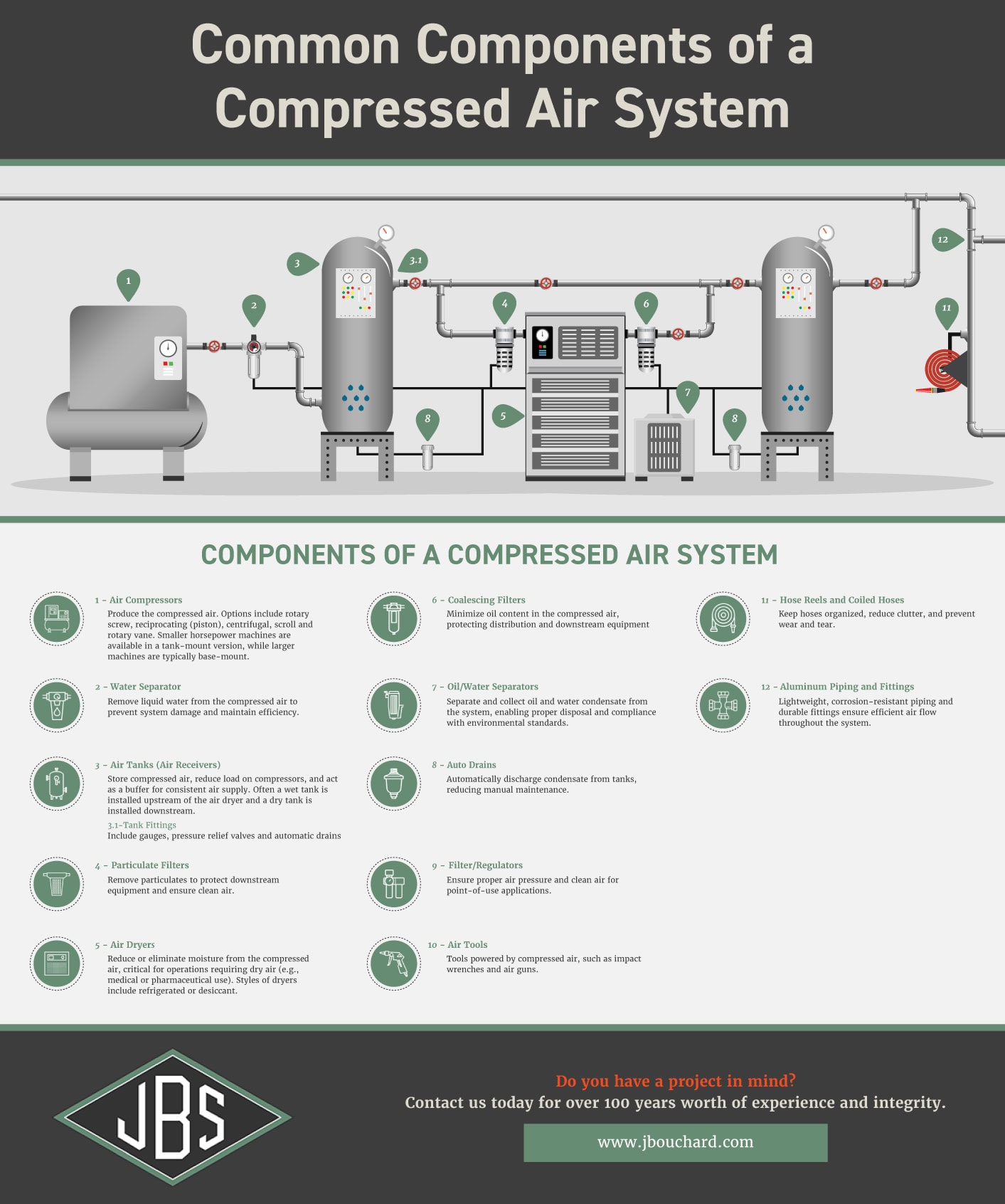

Air compressor installations typically involve the air compressor unit, valves, piping, gauges, filters, controls and an air dryer. The main areas of improvement for this project were the compressor units and piping.

The team at John Bouchard & Sons designed the equipment and piping layout, then completed the full installation of air compressors. This included the compressed air piping system to connect the new machines to existing plant air and the ventilation system necessary for proper airflow through the compressor room. The project included replacing the client’s outdated compressors with the following:

- Three Gardner Denver 200 HP G2 Modulation Units for plant air

- Founded on slow-speed, 1800 rpm design principles the new Electra Saver II G2 rotary screw compressors feature super-sized bearings and up to 40 percent larger airends than the competition. The larger airends, running at slower speeds, maximize efficiency and reduce wear and tear, while the permanent alignment of the airend and motor ensure maximum coupling and bearing life.

- Two 30 HP AirStations providing air for mechanical stamping presses

- Gardner Denver’s L Series line of fixed speed compressors uniquely combines simplicity with cutting edge design. The L Series rotary screw air compressor exceeds performance expectations, while maintaining high efficiency levels. The tank-mounted AirStation model comes complete with a tank-mounted refrigerated air dryer, providing a compact footprint for a complete compressed air system.

The Installation Process

For successful integration of the new compressor system, the team at John Bouchard & Sons implemented a six-step systematic approach:

- Site assessment. We comprehensively evaluated the facility’s layout, existing infrastructure, and operational requirements.

- System design. We tailored the compressor system design to maximize efficiency and minimize downtime.

- Equipment installation. We installed the Gardner Denver compressors, piping and ventilation to meet the client’s operational needs.

- Structural modifications. An exterior wall was removed to facilitate the removal of the old compressors and the installation of the new machines.

- Testing and commissioning. We performed factory startup testing to ensure the system met performance and safety standards.

- Training. We provided comprehensive training to Autokiniton personnel for safe and efficient operation.

The Outcome

The newly installed compressor system delivered impressive results:

- Improved efficiency. With their old compressor system, Autokiniton had to run all three units to provide sufficient CFM for their facility. Now, they only need to run two compressors simultaneously to provide enough air, reducing energy consumption and operational costs.

- Increased reliability. The modern equipment and restructured systems have minimized downtime.

- Enhanced safety. Upgraded ventilation and piping ensure compliance with safety standards.

- Customer satisfaction. Autokiniton was pleased with the smooth installation process and the new system’s superior performance.

By addressing the client’s needs with precision and expertise, John Bouchard & Sons exceeded expectations, delivering a solution that meets operational goals and allows for system redundancy in the event of downtime.

Contact John Bouchard & Sons for Innovative Solutions

John Bouchard & Sons is dedicated to delivering innovative, sustainable, and efficient solutions for industrial challenges. Whether you’re upgrading existing equipment or seeking new installations, our team is ready to help. Contact us today to learn how we can support your business goals.