Industrial Gearbox Repairs

John Bouchard & Sons Co. offers comprehensive extensive gearbox repairs and rebuilds, including field service at your facility and in-house repair in our machine shop. Our team of highly experienced machinists, millwrights and technicians specializes in rebuilding a wide range of gearbox makes and models, providing service across the Mid-South.

Gearboxes are critical components in industrial machinery, responsible for transferring power and torque between motors and moving machinery parts. Because they are essential to the manufacturing process, malfunctioning gearboxes can result in unexpected downtime and lost profit. To prevent issues, familiarize yourself with common gearbox problems and the benefits of our industrial gearbox repair services.

Common Gearbox Problems

Several issues can lead to gearbox downtime. Here are some of the most frequent problems:

- Gear wear and tooth damage: Excessive wear and tear on a gearbox can damage or chip the gear teeth.

- Bearing failure: Bearings are critical components of gearboxes. When a bearing fails, it can cause overheating, increased noise and vibration issues..

- Seal leakage: A damaged seal can both allow external contaminants to seep into the gearbox, and cause oil to leak out, leading to internal damage and malfunction.

- Misalignment: Shafts that become incorrectly aligned may cause excessive stress on surrounding parts, leading to premature gearbox malfunction.

- Overloading: Overloading a gearbox beyond its rated capacity can result in premature failure.

Gearbox Repair Services

Industrial gearbox repair services from John Bouchard & Sons, Co. involve several steps.

- Inspection: Our technicians perform a thorough inspection using specialized tools to diagnose the issue.

- Disassembly: The gearbox is marked and disassembled to access all components, including bearings, gears, shafts, gaskets, and seals.

- Cleaning: All components are meticulously cleaned to remove lubricants and debris.

- Failure Analysis: Technicians analyze the parts to determine the cause(s) of failure and assess which parts remain usable and which require replacement.

- Quoting: If the customer has not already approved a full overhaul, then office staff will provide a quote for the full repair recommended. Sometimes this involves a rebuild vs. replace option, depending upon the size and price of the gearbox as well as the condition of components.

- Machine Work: Our machinists perform lathe and/or mill work to return machined surfaces to factory tolerances.

- Reassembly: The technician then rebuilds the gearbox to OEM standards by installing repaired or replaced shafts, gears and other components, as well as new bearings, seals and gaskets.

- Quality Assurance: During and after reassembly the gearbox is tested for tolerances and functionality to ensure the unit performs to the manufacturers’ standards.

- Repaint & Reinstall: The gearbox is painted, then delivered to the customer. If the customer prefers, our field technicians will then reinstall and startup the equipment on-site.

Benefits of Professional Gearbox Repairs

Replacing a gearbox can be costly, both in terms of time and money. Often, repairing the gearbox is the more economical option, as it is typically faster and less expensive than a complete replacement.

Save Money

Regular maintenance and inspections by experienced professionals can identify potential issues before they escalate, preventing more expensive repairs or replacements in the future and extending your gearbox’s lifespan. Repaired gearboxes also operate more efficiently, reducing energy consumption in your facility.

Save Time

Timely gearbox repairs can significantly minimize production downtime compared to a complete replacement. Choose John Bouchard & Sons Co. for your repairs, where our expert technicians efficiently diagnose and resolve all types of gearbox issues.

Gearbox Repairs From John Bouchard & Sons Co.

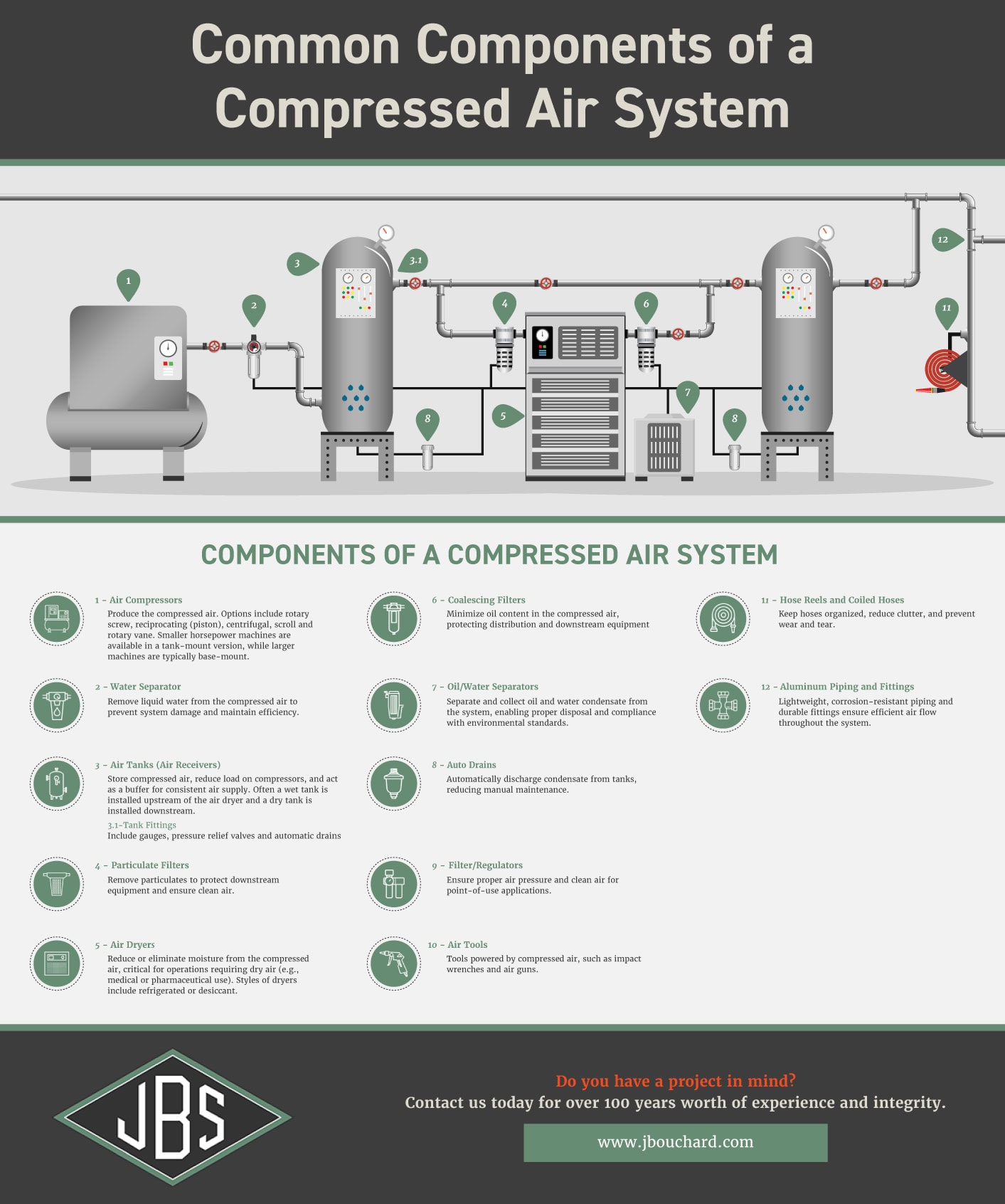

With over 100 years of experience, John Bouchard & Sons Co. understands the mechanical systems in which your gearboxes operate. In addition to gearbox rebuilds, we offer service & repair of pumps, air compressors, motors and other rotating equipment, as well as a full line of compressed air products.

Types of Gearboxes We Repair:

- Bevel Gearboxes

- Coaxial Helical Inline Gearboxes

- Helical Gearboxes

- Planetary Gearboxes

- Shaft Mount Gearboxes

- Worm Reduction Gearboxes

- Worm Gearboxes

Applications of Gearboxes We Repair:

- Agitators and Aerators

- Boring Machines

- Clarifiers

- Conveyors

- Crushers

- Extruders

- Fans & Cooling Towers

- Feeders

- Grit rakes

- Mills

- Mixers

- Presses

- Processing Equipment

- Pumps

- Sludge Handling

Contact us to learn more about our industrial gearbox repair services or to get a customized quote.