Owensboro Grain Chooses JBS and Gardner Denver for Air Compressor Upgrade

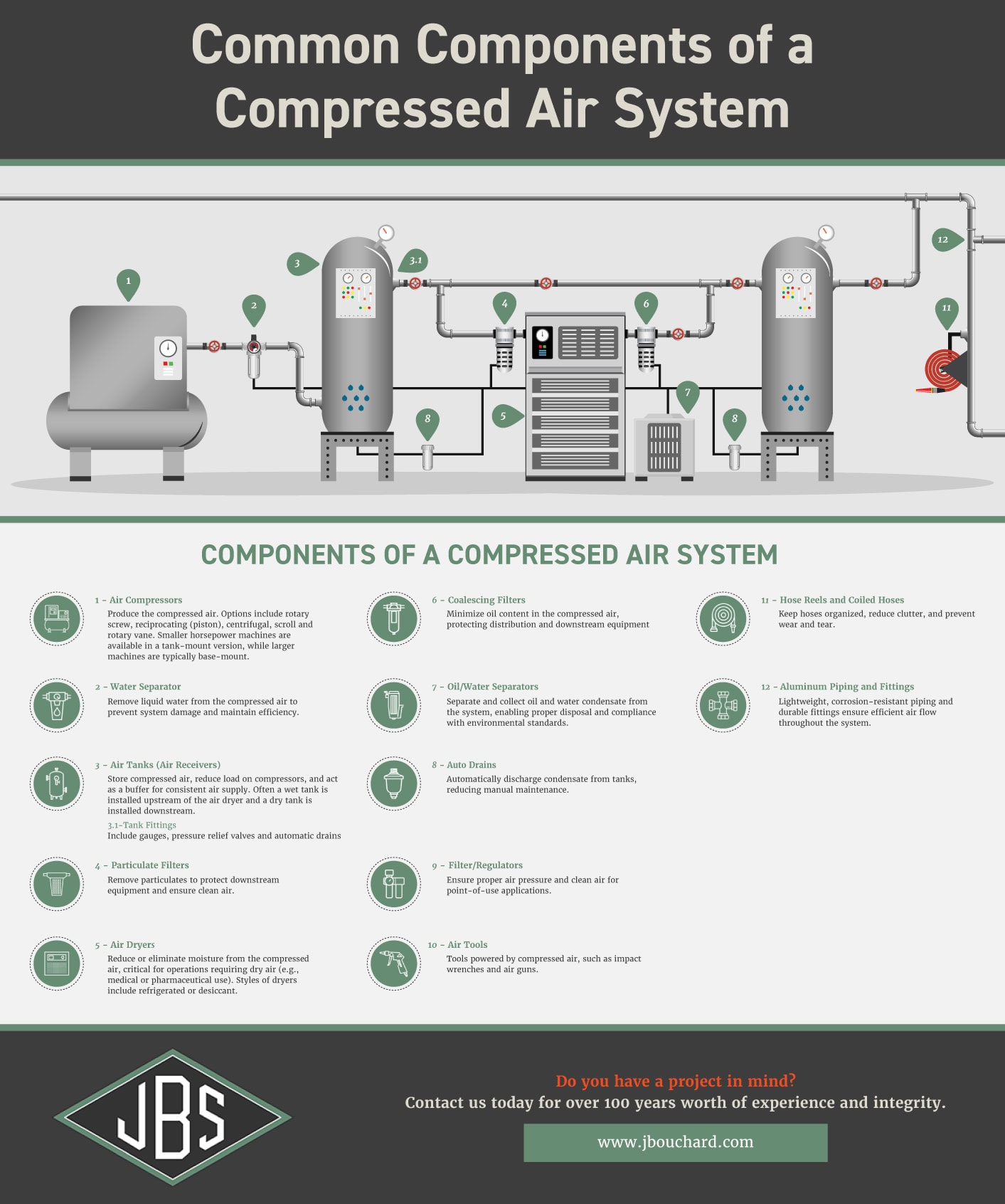

JBS has continued our longstanding relationship with Owensboro Grain Company (OGC), a West Kentucky food processing manufacturer, through its recent compressed air system installation. We supplied OGC an upgraded 150hp air compressor, a heatless desiccant dryer, compressed air piping, and a replacement 500-gallon air receiver storage tank.

Owensboro Grain was founded in 1906 as a small grain merchant on the Ohio River, in Western Kentucky. Today it operates a fully integrated soy processing facility, producing products, such as protein meal and hull pellets for animal feeds, crude and degummed oil, lecithin, various blends of refined vegetable oil for human consumption, biodiesel, glycerin, and industrial waxes. OGC was recently acquired by agricultural giant, Cargill.

Updating Legacy Compressed Air System

OGC’s legacy GD compressor has logged over 125,000 hours, utilizing the original airend, which has yet to be rebuilt. Through ongoing conversations with JBS, OGC maintenance staff proactively planned for an updated compressed air system. The legacy compressor was left in place and converted to a backup, redundant system. Our compressed air specialist suggested upgrading to Gardner Denver’s 150 HP, L-110 RS compressor. The LRS’ compact design and quiet operation allow for greater installation flexibility, making it well-suited for various applications, including OGC’s mechanical room.

In addition to the compressor, JBS supplied a Gardner Denver DGH-9305 Heatless Desiccant Dryer. This dryer is considered “heatless,” since it utilizes an absorption process, rather than heat, to dry the air. In this process, the air is passed through a bed of desiccant material, removing moisture from the air by attracting and trapping it. OGC’s air lines travel through an outdoor environment, which is regularly exposed to freezing temperatures; therefore the low moisture content of air produced by the desiccant dryer protects the pipes from freezing.

Compressed Air Uses

The compressed air supplied by the new system will run diaphragm pumps, actuated valves, and other pneumatic equipment in the plant. Through the use of this equipment, Owensboro Grain produces up to 45 million gallons of biodiesel a year. The Kentuckiana company also produces soybean oils, which are used for baking, food processing, and industrial products such as paint, plastic, and ink.

JBS has been privileged to provide compressed air maintenance and repair services to OGC for several years. We are grateful that their satisfaction is demonstrated by this renewed trust: sourcing their upgraded system through our Evansville, Indiana compressed air team. We look forward to supporting Owensboro Grain through a preventative maintenance agreement over the coming years.