Signs That Your Compressor Needs Service

Like many other types of equipment, air compressors require regular maintenance to ensure their continued functionality and efficiency. The following are some of the specific signs that your compressor needs service.

Operating Hours

Operating hours are among the main considerations when determining whether you need air compressor service. The majority of compressor manufacturers give regular maintenance recommendations based on either calendar time or operating hours, depending on which comes first. Most all manufacturers warranty terms require preventative maintenance at these intervals. The reason for this guideline is that, depending on the frequency of use, your compressor experiences varying degrees of wear and tear over time.

By following recommended routine maintenance schedules, you can:

- Avoid breakdowns: Proactively addressing potential mechanical issues with your compressors could help you reduce the risk of system breakdowns and subsequent downtime. Conducting regular maintenance will also minimize expensive repairs.

- Optimize performance: Consistent maintenance also enables compressors to operate at maximum energy efficiency with the right airflow and pressure levels.

- Increase equipment longevity: Maintenance will keep your air compressors in good working condition and extend their lifespan, eliminating the need for frequent and costly replacements.

Extreme Conditions

Certain environmental conditions can also lead to compressor wear. A dirty or dusty operating environment can cause particulate to quickly build up or clog coolers and filters, negatively impacting compressor performance and efficiency.

Generally, the more particulate production there is in a facility, the more frequently you’ll need to perform air compressor service. Woodworking mills, auto body shops, and other similar facilities are examples of environments that will need more maintenance for compressors and other equipment.

Temperature Extremes

Extreme high and low temperatures can also impact compressor maintenance needs. Specific environmental factors could include the following:

- Hot weather: High summer temperatures in Tennessee, Kentucky and Indiana can lead to overheating that can damage compressors. In these environments, regular cooler, oil and other maintenance checks can help minimize heat damage.

- Cold weather: Cold temperatures can also cause functionality issues or damage, including frozen lubrication and internal components. Routine maintenance can help prevent or address these issues in low-temperature environments, like the cold winters experienced in the Mid-South and Midwest.

- High humidity: In environments with high humidity levels, moisture can lead to rust buildup and corrosion in compressor components. Operators must keep components consistently dry and perform regular maintenance.

- Operating outside of acceptable temperatures: Compressors must operate at recommended temperature ranges, which manufacturers typically disclose. Operating at temperatures that fall outside this range could lead to accelerated wear and damage.

Air Compressor Services From John Bouchard & Sons Co.

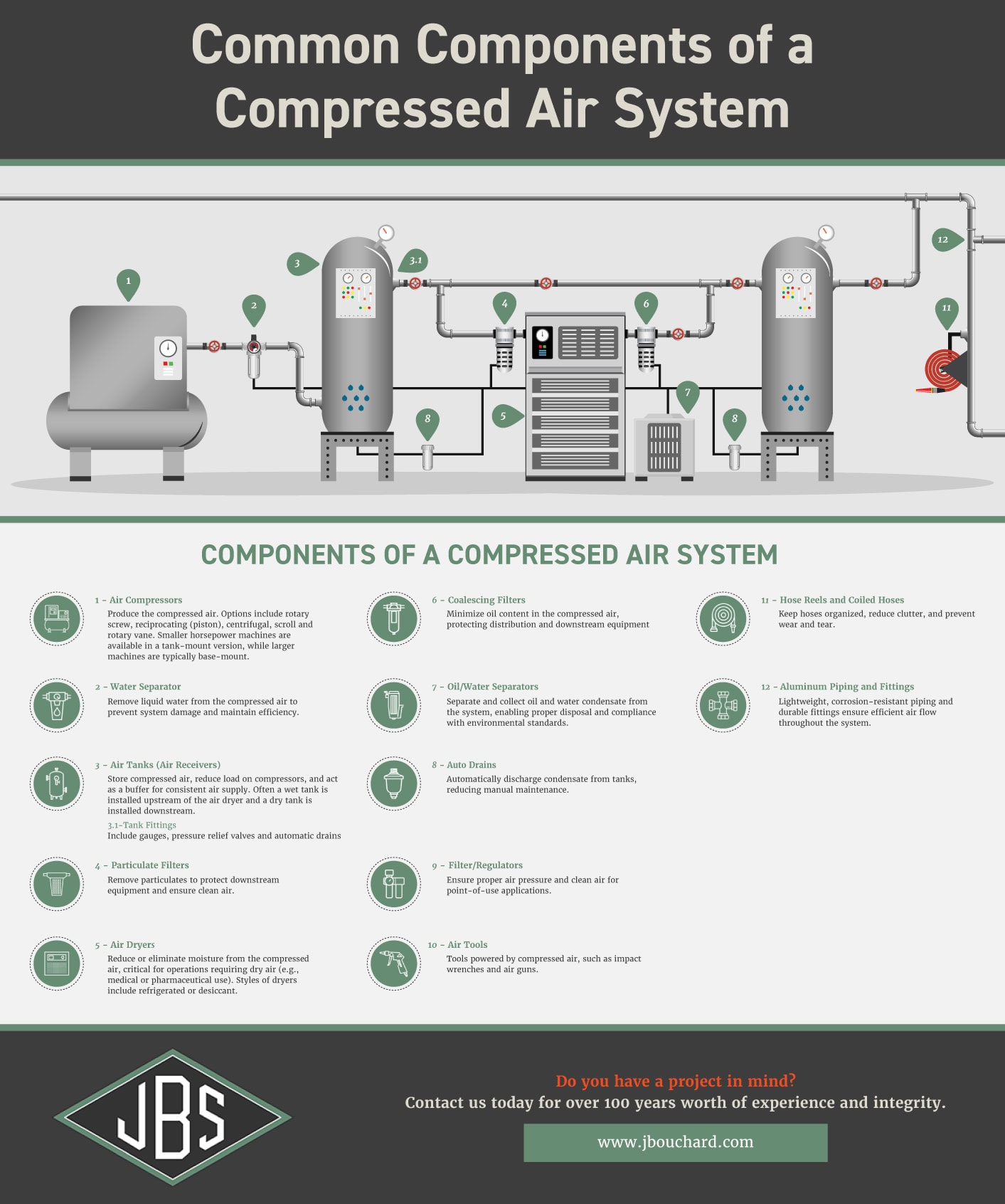

Regular maintenance for air compressors and wider system components such as dryers, filters and drains can help ensure your equipment continues to work at peak performance. John Bouchard & Sons Co. provides routine and preventative maintenance services for air compressors as a factory service provider for top brands, including Gardner Denver, Comp Air, Boge, Parker, and more. We can also service any brand of compressor. Our connections with the manufacturers enable us to provide consistently dependable and effective air compressor service for our customers.

We also provide emergency repairs, in-house airend rebuilds and a comprehensive line of compressor rentals to suit your unique needs. For help determining your air compressor’s maintenance schedule or to make a service appointment, contact us today.