1837 – Jean Baptiste Bouchard was born, the 6th of nine siblings, in Trois Rivieres, Quebec Canada.

At age 12, his family moved to Westport, Essex County, NY. There, he joined his father and brothers, in the trades of machinist and engineer, operating an iron foundry together and likely learning English along the way. Twelve year-old Jean Baptiste’s name was anglicized to “just plain, ole John,” his great grandson would later explain.

1857 – At 19, John Bouchard moved to Chicago, initially working in the brick industry, before transitioning to meatpacking.

Around age 28 he married Phoebe Van Norman of New York, the same year that the Chicago Union Stockyards essentially married livestock suppliers to its unprecedented consolidation. John clearly invested his energies in his work and family. Phoebe gave birth to a daughter, Mary (Mazie Young) in 1867, to John Eugene, named for his father as well as his father’s brother, in 1870, and to James William in 1873. John’s parents likely never met the children as they both died in NY in 1869 when John was just 32.

When the Great Chicago Fire of 1871 destroyed the entire southwest, business and residential side of the city,

1880 – Bouchard received a US patent for his Hog Scraping Machine, the first of three patents.

William Kincaid of Fowler Brothers Packing had designed the first successful hog-scraping machine in 1876. Bouchard, a friend and colleague of Kincaid’s, came up with a design using metal spools and flexible steel scrapers. Bouchard was then recruited by Michael Cudahy to Armour & Co., where he and Cudahy collaborated to add counterweights to hold the spools against the carcass, which made for a superior machine, which helped Armour to process pork “at the rate of a hog in less than three seconds – an average of 1400 an hour.” -Chicago’s Pride: The Stockyards, Packingtown, and Environs in the Nineteenth Century.

1880s – John Bouchard served as chief engineer of Armour & Co., supervising 75 men.

He was paid a $4,000 salary (10x the average factory worker) to oversee “the entire motive power and machinery” of the plant, which was one of the largest factories in the nation, employing 4,000 workers during peak season and processing 1.5 million animals per year. Bouchard’s personality was described as “taciturn.” Owner, P.D. Armour gave engraved gold pocket watches to both John Bouchard and John E. Bouchard in appreciation for good work.

Bouchard also secured patents for an innovation to switches for overhead tracks (1889) and for a refrigeration machine (1885), consisting of a horizontal engine directly connected to a center crank, which drove two vertical, single-acting ammonia compressors. Sixteen 75-ton machines, valued at $20,000 each

1900 - “John Bouchard and Son” opened on Harrison Street in Nashville.

At the turn of the 20th century, father John Bouchard (63) and son James (27) set up a workshop and small foundry together on the corner of Cumberland (later 11th Ave. N.) and Harrison Street, Nashville, Tennessee, where the company headquarters still stands. The city’s Union Station opened the same year, telephones were in wide use, and William McKinley sat in the White House. In 1901, they advertised in the Nashville American as “Engineers, Founders & Machinists”.

1905 - Plumber, John E. Bouchard joined his father and brother at “John Bouchard & Sons Co.”

Nashville plumbers’ union wages were $3.25 per eight-hour workday. News accounts from this period suggest there was friction between journeymen plumbers and master plumbers, who were represented by separate unions, and that the journeymen may have suspected employers of exploiting those differences by hiring underage and Black employees at cheaper wages. By 1905, an agreement among both unions and employers established a base wage of $3.25 for an eight-hour workday. Perhaps the friction motivated John E. to join his father and brother on Harrison Street.

1908 - Bouchard & Sons expanded to manufacture ice factory machinery.

The company announced “a most important addition to their machine works and foundry in Northwest Nashville, extending the plant for the purpose of the manufacture of ice factory machinery.” The machinery consisted of single-acting ammonia compressors, with a daily capacity of up to 10 tons. It was said that the Bouchard company had “probably the only plant in the South where such equipment could be manufactured.” Principals of the company “have had experience in Chicago in the manufacture of ice factory machinery on a much larger scale and have full understanding of the new department.”

The company installed refrigeration equipment for the Hermitage Hotel, Nashville’s first $1 million building, as well as Standard Candy, Tulane Hotel, Belmont College, Stahlman Building, and Howe Ice Company in Chattanooga, Birmingham and Atlanta, among many others.

1913 - John, the founder, and son John E. incorporated John Bouchard & Sons Co.

The company was incorporated in 1913 “for the purpose of engaging in and carrying on the business of machinists, general contractors, buying and selling all manufacturers’ supplies and materials, pertaining to or in any wise connected with a general machine shop or contractor’s business, and in general to carry on and conduct all business connected with and pertaining to the operation of a machine shop, or that of general contractor.” The first board meeting was held September 13th at the Stahlman Building, where Bouchard had recently installed a refrigeration plant. Founder John was elected president in 1913, and son John E. was named secretary. J.H. Howe was elected vice president.

1916 - John Bouchard died; John E. Bouchard (46) became president.

At the age of 79, Bouchard died two days before Christmas. His death was noted one of 500 most significant events in Nashville in this year. John E. Bouchard, who was 46, now led the company through the World War I era, amid both challenges and substantial growth.

1918 - Company advocated for WWI U.S. Liberty Bonds and purchased $24,800 worth.

John Bouchard had been one of the first members of the Rotary Club of Nashville. A group of businessmen had formed the club in November, 1913. Since those early days, each of the successive leaders of the company has been active in the Rotary Club, and many people within the company have volunteered time to serve Nashville through charities it sponsors. In April 1918, John E., also a registrar for Davidson County’s wartime draft board, served on Rotary’s “Liberty Loan Committee” motivating Nashvillians to purchase bonds to support the U.S. campaign in WWI, which was now affecting the globe. He put his money where his mouth was; as of 1920, the company owned $24,800 worth of U.S. Liberty Bonds and $83.60 in U.S. War Savings Stamps.

1919 - Union Ice Cream Co. ammonia tank explosion killed one and injured three Bouchard machinists.

On May 21, 1919, “four Bouchard machinists were seriously injured when a large ammonia tank in the rear of the Union Ice Cream Co. exploded” as the Nashville Banner reported. One lost an eye. Another was paralyzed from the waist down. The others suffered serious cuts and burns. One may have soon died. Of the affected, Edward Ewing sued Bouchard and Union Ice Cream for $20,000 in damages. No documentation was found of the resolution to this crisis. Advertising in 1924 revealed that much ice cream was “made possible” at the Union Ice Cream Company’s “beautiful new plant” because of Bouchard’s “installation of York refrigeration machinery.”. (Union was later known to generations of local ice cream lovers as Sealtest.)

1920 – "Individual merit should be rewarded,” was Bouchard’s answer to Machinists Union demands of $1.25 per hour.

By 1920, tensions at many Nashville companies were high between employers and cash-strapped workers. The local machinists’ union published newly proposed rules and requirements of employers, prompting a rather direct response from a collective of nine machine shops in Nashville. The employers published their response to the union’s demands through copy-heavy advertisements in both papers. The text began with the employers setting out the workers’ 12-point negotiating position, apparently verbatim from a document the local branch of the International Association of Machinists had submitted in April.

1921 - New foundry opened to employ 50 men and operate at night.

The Nashville economy eventually began to level off in late 1921. By September, the new foundry had been opened behind the machine shop and had made its first pour of cast iron. It was on track to employ 50 men at full operation. News reports called it, “one of the most complete of its kind to be found anywhere in the South,” and also “fully equipped for operation at night.” The foundry men said it was, “blowin and goin.”. Located where the current high bays of the machine shop sit, the new facility operated an electric crane, a device that had just started to be used in manufacturing facilities during the previous decade. The Tennessean declared, “Nashville will be greatly benefitted by this new foundry for it will be able to take care of a large portion of work that has been in the past delayed.”

1924 – Montgomery, AL branch opened to manufacture leather belting.

In 1924, John Bouchard & Sons expanded its reach to Montgomery, Alabama, opening a facility in the state capital meant to focus on manufacturing leather belting for industrial use. Bouchard had been manufacturing their own “Lyda Brand” belting in Nashville. Belt-and-pulley mechanisms were a staple of operations for numerous company clients—although technology advances would soon change things dramatically. A local chamber of commerce official was quoted expressing hope that JBS would bring greater operations, but no such prosperity ensued. The last known record of the Montgomery branch was in 1926.

1925 - Designed and installed refrigerating and ice plant for new Vanderbilt University Hospital.

In 1925, when what is now Vanderbilt University Medical Center opened as the first combined medical school and hospital under one roof in the United States, it relied on a refrigerating and ice plant designed and installed by Bouchard. Bouchard tradesmen have not stopped servicing and building expansions at the hospital since. Today, VUMC is the largest comprehensive health system in the Mid-South. It performs more heart transplants annually than any other medical facility in the world, serves as the region’s Level 1 Trauma and Burn Centers, and employs more people than any other non-governmental organization in Middle Tennessee. John Bouchard & Sons Co. has served this medical institution from its beginning.

1925 - Automatic Fire Sprinkler Department organized to increase firefighting efficiency and decrease insurance costs for customers.

In the mid-20s, emergency response to a fire alarm had limitations. In 1925, Bouchard formally organized its automatic fire sprinkler division to provide more efficient means of fighting fires and, consequently, insurance rate reductions for its customers. The company designed systems for among others, Nashville Hardwood Flooring, H. E. Parmer, May Hosier Mill, Murfreesboro Woolen Mills, Morgan & Hamilton Co., Hermitage Mills, and Tennessee Hickory Products Co.. “Sprinkler systems have remained the same—you fight a fire with water,” John E. III later clarified.

1926 - Revolutionized Nashville theater-going with a $50,000 cooling system at Tony Sudekum’s Capitol Theatre.

Public indoor air conditioning proved to be the distinct, competitive advantage that Bouchard could furnish entrepreneur Tony Sudekum when he opened the Capitol Theater at 531 Church St. in 1926. Having spent a reported $50,000 on its cooling system, designed and installed by Bouchard, he advertised: “Tons of Ice to Cool the Capitol: The only theater in Nashville having its own refrigerating plant—a refrigerating capacity equal to melting 150,000 lbs. of ice a day.” “It is accepted Sudekum family lore that A/C was as, if not more, important to the success of Crescent Amusement Co than the playbills themselves – in Southeastern summers most especially.” – Marc Stengel, president of Kermit C. Stengel Co. and great-grandson of Tony Sudekum.

1928 - John E. Sr., began his Nashville Boys Club leadership to help build thousands of boys into good men.

He was in his mid-50s and in the first of 13 years serving as president of the club when a profile in the Tennessean gave this insight : “John Bouchard, the head of the business, is a busy man. But when he is asked to relax and talk about his big business for a while, he will do it… He launches into something about the Nashville Boys’ Club. That’s his “big” business, his nearest, his greatest recreation. He is a sight prouder of being the president of the Nashville Boys’ Club apparently than he is of holding the like office in John Bouchard & Sons Company. Mr. Bouchard has carried into office as president of the Boys’ Club the same ability and personality that built his business…. He acknowledges that he considers it a greater work to help build a man than to build a business.”

1931 – Work schedules and compensation shifted so that no payroll is missed during the entire Great Depression.

Records from the 1930s indicate that the conservatively managed enterprise remained in operation throughout the decade and had few if any layoffs. Still, everyone felt the pinch. In 1932, the board voted to decrease the president’s annual salary from $10,000 to $8,000. Work shifts were staggered to share the lessened load. For the second year in a row, company assets declined by five percent. Eighty years later, the fourth-generation leader John E., III, fell somber in telling that, “The shop didn’t work but about two or three days a week during the Depression. It was a bad time.”

At such a time, completing a new brick addition to its headquarters, which added an entire third story in the summer of 1931, was a bravely confident move. The company maintained “a payroll of approximately 135 men,” The Tennessean reported, that “the size of this payroll had not been diminished during the prior years,” and that the firm stated they had “continued to operate at full force.”

1935 - Electrical repair operations organized into an official department.

In June 1928, Bouchard announced the hiring of R. E. Pegram, to run the electric motor repair shop, a precursor to the Electrical Department, which was officially organized seven years later for subcontracting work….Buoyed by projects for Dortch Stove Works (now The Factory at Franklin), Genesco, and Werthan Bag, among others, the Bouchard balance sheet recovered with strength in 1935. The company had increased inventories, sales were up, and cash position remained strong.

1938 - Installed fire sprinkler system in Eastern State Hospital, Knoxville, TN.

Bouchard sprinkler fitters headed over the Cumberland Plateau to complete a $46,979 contract, installing an automatic fire sprinkler system at Eastern State Hospital in Knoxville (now Lakeshore Park). The installation was a safety measure, and the use of the system covering six buildings was expected to significantly “cut the institution’s annual insurance premium from $23,000 to $3,000,” according to Wallace Edwards, hospital administrator.

1941 - John E. Bouchard, Sr. died suddenly. John E. Bouchard, Jr. becomes president at 29 years old.

John E. Bouchard, Sr., felt unwell in early 1941. His physicians put him in a hospital, but they allowed him to make a brief visit to his office on February 1. Along the way, accompanied by his wife, Mary McMurry Bouchard, he stopped at the Nashville Trust Company to retrieve a document from the company’s safe deposit vault. A moment after he entered the vault, he fell dead from a heart attack. He was 70 seventy years of age. His son, 29-year-old John E. Bouchard, Jr. was thrust into leadership just months before the US entered WWII.

1942 – Supported WWII effort through Defense infrastructure jobs.

Bouchard completed jobs at Camp (now Fort) Campbell, Sewart Air Force Base, Fort. Knox, and Nashville’s Army Air Classification Center. The plumbing department installed plumbing for 200 homes in Berry Hill Gardens of Nashville. An emergency presidential order issued days after the December 1941 Japanese attack on Pearl Harbor created the Office of Defense Transportation, which held broad wartime powers to regulate domestic transportation equipment. In November 1942, the ODT granted Bouchard a “Certificate of War Necessity” for its fleet of commercial trucks. The company was initially licensed to use seven trucks, driving a total of 100,800 miles each year and using 1,740 total gallons of gasoline each quarter.

1948 – Company exceeded $1 million in annual revenue.

In 1946, the question of how to compensate talent and hard work took the form of the first recorded bonuses for salaried employees, those who often carried measurable responsibility after the quittin’ time whistle blew. Over subsequent years, bonus distributions rose as profits and performance did. In 1948, after more than a year of discussion, $30,000 was budgeted to build an expansion– a pipe shop/warehouse- on the lot adjacent to the existing Harrison Street office and shop. For a new company truck and car, $5,000 was lined- out. The next year, as motor vehicles were becoming increasingly vital and valuable to the construction business, the board committed $7,500 further in “rolling stock.” After all, the company was now crossing the $1 million annual sales threshold.

1957 - John E. Bouchard III joined the company.

Though he had swept the floors since he was 15 and interned during college, Jack Bouchard became a full-time employee after graduating from Vanderbilt University School of Engineering in 1957. By 1960, Jack was tasked with managing a substantial job to install plumbing, heat, and air conditioning for the new suburban Green Hills Office Building. This is how he told it: “You know sometimes contractors and architects don’t see eye to eye. …I couldn’t get the pipe high enough in the ceiling to miss the ceiling grid, so I asked the architect if I [could] drill holes in the concrete slab above and put a washer and a nut—so I can raise the pipe up against the joist. He said, ‘Alright, I guess that’s ok.’ We drilled all those holes and had the pipe up and, then a torrential rain came. Water was standing on the roof 4–5 [inches] deep … and it was dripping through all those holes. I finally faced him and, he was so mad he was trembling. He said, ‘you have ruined my building!’” Bouchard did fix the problems, and the building is still in operation in 2025, sandwiched between the Green Hills movie theater and Green Hills Mall.

1958 – Kroger warehouse fire started by acetylene torch sparks.

Kroger claimed that Bouchard employees set off the blaze as they were using an acetylene torch to install a vent pipe on the building’s roof. Sparks of molten metal ignited a large stack of Styrofoam insulation, starting a fire that burned for more than three hours. Some witnesses said it “exploded” like gasoline…The men had been working on an expansion to the warehouse. The Nashville Banner reported that “what could have been a disastrous explosion was averted when a 1,000-gallon tank of ammonia burst into flame instead of exploding.” …After a 1964 jury trial lasting almost three weeks, the court ruled that Kroger, its prime contractor, and subcontractor Bouchard were all liable for negligence. The $775,000 case was dismissed, and Kroger could not recoup money from either defendant.

Smoother 1958 projects included, sprinkler work for Braid Electric, laundry and boiler room equipment installations for Baptist Hospital (now Ascension St. Thomas—Midtown), and for the City of Pulaski, sewer lift station and high service pump installations.

1960s - Fire sprinkler work for many Kentucky customers.

Sprinkler work of the ’60s included system installations for Kentucky customers, Kentucky Pants Co. (Glasgow), Kentucky Pallet Corp. (Scottsville), and Logan Manufacturing (Russellville). JBS completed projects for Tennessee customers, Genesco, Colonial Shirt Co. (Jamestown), Cleveland Overall (Alexandria), Western State Hospital (Bolivar), State Stove & Manufacturing Co. [now modern customer A. O. Smith] (Ashland City), Cookeville Golf and Country Club, the Belcourt Theater (Nashville), the Franklin Theater (Franklin), and the Arcade in downtown Nashville.

1963 – New foundry constructed in Nashville.

In December of 1962, young Jack Bouchard told the board that with recent growth, “the company had outgrown its present iron and brass foundry… [and] unless steps were taken to overcome this difficulty that… he was of the opinion the company might lose some of its present business. He further stated a location had been found at the east side of 18th Ave. between [the Tennessee Central and Louisville & Nashville] railroads”…With that, a fourth generation launched the expanded foundry operation by greater measure. And though showing signs of “sinking” from time to time, it stayed fueled by Jack’s passion for pouring iron and became one of the most profitable areas of the business and a benchmark in his legacy of leadership. “I believe we happened to be at the right place at the right time…”

1966 - $3+ million in revenues for the first time. 300 Nashville union plumbers went on strike.

On April 1, 1966, a contract between Plumbers Union Local 352 and major contractors in town expired. The following morning 300 plumbers went on strike. The union had been negotiating since January with John E. Bouchard, Jr. and Robert Bibb of Nashville Machine & Supply Co. but, disagreements over fringe benefits and management’s demands for a no-strike clause had not been resolved. Bouchard said, “We haven’t asked for anything that is a detriment to the union. We, of course, are open for another meeting anytime.” He spoke for the concurring contracting firms that “must halt plumbing work pending settlements of the disputes and will not call in non-union plumbers.”

1969 - Helicopter used to install 23 HVAC units on roof of Tennessee Tufting in only two hours.

In February, 1969 the company made lighter front-page news in the Tennessean under the headline “Business Gets Lift with Copter.” As the article explained, “Installing air conditioners is a breeze, the way they do it at the Tennessee Tufting Co. these days: they do it by helicopter. The helicopter launched a new era in the construction business here, according to Gordon Norris, superintendent with John Bouchard & Sons Co., the mechanical contractor for the Tufting’s new [275,000 square-foot] building in the Cockrill Bend Industrial Park.”

1969-70 - John E. Bouchard, Jr.’s sudden death was one of many challenges.

Company treasurer is let go; 35-year-old John E. Bouchard, III (Jack) becomes new president; Employee falls through platform and dies at AVCO sprinkler job; Metro cites the foundry for air pollution violations; Bookkeeper dies; Mrs. John E. Bouchard, Jr. dies. Employees quit to start competing companies; Jack Bouchard meets Jesus Christ.

1972 – Bill & Ira Gadd retired with a combined 106 years of service.

Family connections among Bouchard employees, as well as lifelong service, are recurring themes in the company’s history. Few examples are more impressive than the Gadd brothers, Bill and Ira. Bill Gadd joined the company in 1918, and Ira followed him in 1920, both before the age of 18, and both having lived in an orphanage. According to Pat Smith, “Bill would work here, cleaning up, doing whatever they needed help with doing, just to see what was going on before they would even hire him.” Once on staff, the brothers became standard bearers for workmanship that was “John Bouchard quality.” Bill was named machine department superintendent in 1935, while Ira held the position of lead machinist. Bill passed away in 1989, while Ira lived to the age of 102 before he passed in 2006. In his retirement, Ira would regularly visit the shop to see people or get something fixed. He made it known that he had achieved his two lifetime goals: 1) becoming a millionaire—thanks in part to his wife’s purchase of BellSouth stock over the years— and 2) living to be 100.

1973 - Milton Miller hired to run the foundry operation.

A coke (a derivative of coal) salesman from ABC Coke pitched out a recommendation for Milton Miller from Robinson Foundry in Alexander City, Ala. From the salesman’s circuit he could see Milton was destined for more than his current job. Jack convinced Milton to come and run the foundry. The relational details are what they got straight first. As Milton later said, “I just figured I could trust him…Jack Bouchard let me run my own foundry…I had always said, I would either own my own foundry or I would run one like it was mine by the time I was 30 years old. If I took the job, he would let me run it—that’s what we had talked about. And he did.” The relationship would work out quite well. They fought for contracts together, shared counsel on supply or workforce tensions and often walked laps around the foundry yard, just sorting out life together. Miller would oversee tremendous growth in the JBS castings business across the Mid-South. In 2024, he retired after 51 years as foundry manager.

1975 - JBS celebrated 75 years in business, under single family ownership.

In 1975, John Bouchard & Sons celebrated its 75th birthday. Trucks were rolling, muscles were building and rebuilding, and minds were figuring. A dinner was hosted at Hillwood Country Club to commemorate the milestone. As a part of the 75th anniversary celebration, Bouchard published an advertisement highlighting its history and shared age with Coca Cola Bottling Co. (a longtime customer). The Tennessean also published this: “John Bouchard & Sons, which started here as a blacksmith shop at 1024 Harrison St., has just celebrated its 75th anniversary…. As construction service demands grew, it added mechanical and electrical contracting departments in the mid-20s, and this was followed by addition of an industrial supply division.”

1977 – Jack Bouchard led building of Rotary-sponsored Girls’ Ranch.

From 1976 to 1977, Jack Bouchard, as elected president of Rotary, focused on a project in keeping with his lineage. Previously, the Rotary Club in Jackson, Tenn. had constructed a Tennessee Sheriff’s “Youth Town” for boys who had no other place to live, many of them neglected or abused by their parents. It was successful; however, no similar place existed for girls. Jack led a group within Rotary to make the case for building a girls’ “Youth Town”. He pleaded, “these are children with no place to go, for the judge in Middle Tennessee often has to send them to jail for lack of a place to go….” JBS donated the installation of the plumbing and water systems for the camp. By 1977, five girls had moved in, three of whom were sisters. For years, dozens of girls were given a safe haven from abusive situations at the Girls’ Ranch.

1979 – MetroCenter flood protection pumping station installed.

In the late 1970s R.C. Matthews Contractor, Inc., asked JBS to assist with the building of the flood protection system for MetroCenter. Much of the original 850 acres of the MetroCenter commercial development was subject to annual flooding by the adjacent Cumberland River. The protection system, designed by local engineering firm Barge, Waggoner, Sumner & Cannon, combined a 3 ½-mile earthen levee with a series of interconnecting canals, retention lakes and an automatic stormwater pumping station. JBS assisted in the building of the pumping station. The project was completed in the summer of 1980.

1980s - JBS workers broke away from most unions.

By the early 80s, the merit-shop philosophy spread through Middle Tennessee construction trades, and Jack felt it was time to embrace it more fully for Bouchard. Being so diversified, JBS had been dealing with multiple unions. Ronnie Edwards remembers “every time the contract come due, (Mr. Bouchard) was having to deal with people and they were talking about how they do stuff in Chicago” … De-unionization at Bouchard started with the construction trades, when several long-term employees including Roy Smith came to the same conclusion that Jack had and crossed their picket lines to return to work. By 1985, the construction unions were gone from JBS, setting the stage for a new era of relationship directly between management and the workers, no third-party in between, mudding the waters.

1982 - One foundry employee murdered another in the parking lot.

“I’m in the office, and all of a sudden, the doors fly open, and here they come dragging [Dowdy] in and laid him down in the floor [attempting to render aid]. Of course, everybody was scared or afraid that something else was going to happen. They [his coworkers] thought if they were with me, that they would be safe. So everybody is in that little old office and here we got this one laid out on the floor, and he died right there on the floor…. That was the worst thing that I had happen,” said Milton Miller of the 51 years he spent as manager of the foundry.

1987 - Pumping equipment supplied for new terminal of Nashville International Airport.

John Bouchard & Sons’ 140 employees continued to work hard and prosper through the late 1980s and into the 1990s. With Nashville’s dramatic growth, civic leaders arranged in 1987, for the construction of a vast, new flight terminal at the consequently renamed Nashville International Airport. Bouchard and Ingersoll-Rand partnered to supply all the pumping equipment for the new complex. For extensive fire sprinkler work and other pipe and pump jobs, tradesmen from Bouchard still frequent BNA; the runways, roadways and parking lots are dotted with JBS castings as well.

1988 – Process piping and mechanical equipment installed for Baird-Ward and other printing companies.

In 1988, Arcata Graphics, which acquired the former Baird-Ward printing plant in Nashville, began building a $70 million, 300,000-square-foot plant in Clarksville. Their problem was “they weren’t completely open—weren’t nowhere near open—but they called just out of the blue,” said Ed Patterson who knew the caller from work Bouchard had done at Baird-Ward – installing 11 big air handling units and a large centrifugal chiller for their Powell Avenue facility. JBS jumped in quickly, getting the project back on track.

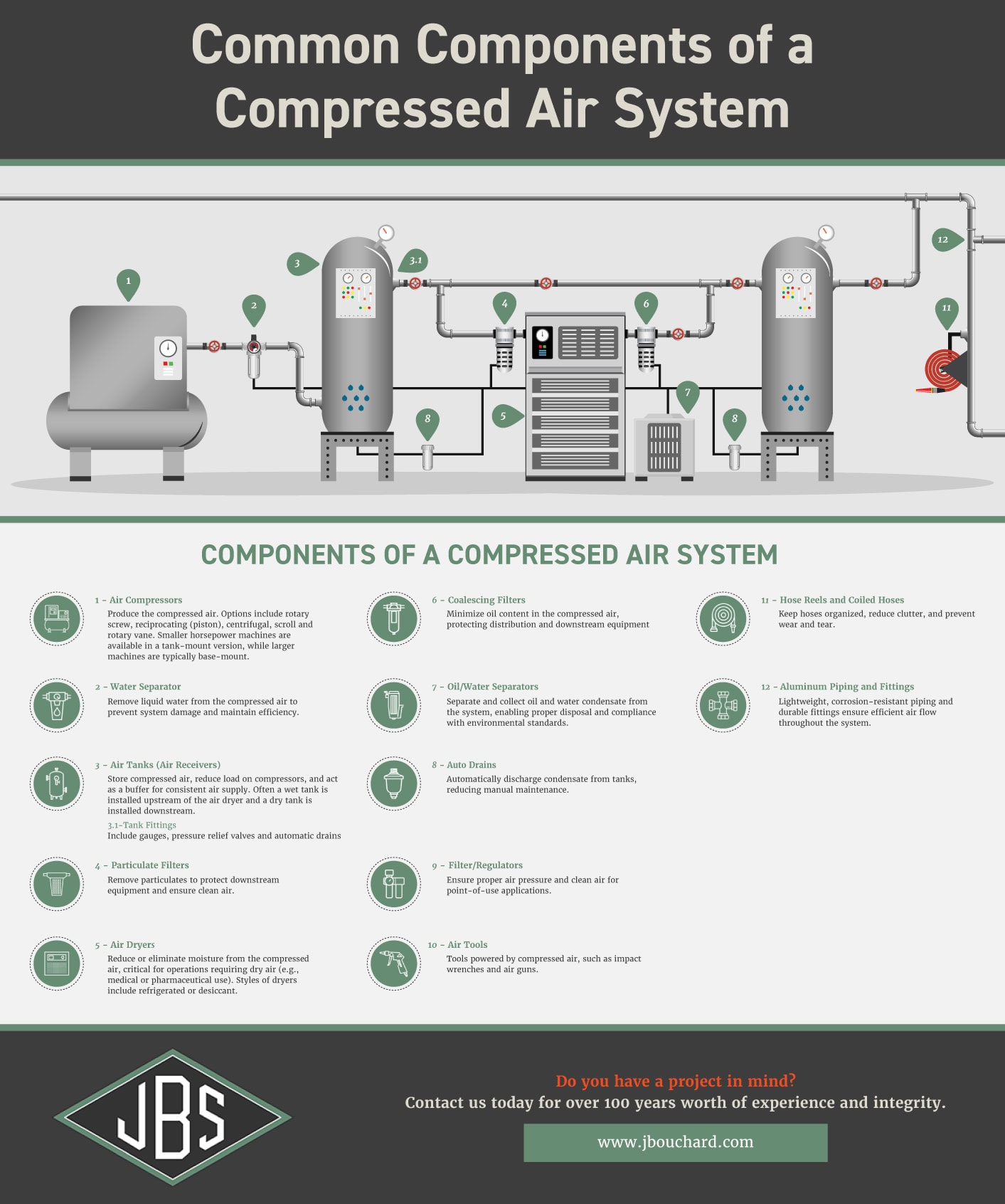

1991 - Compressor Department is formed as JBS becomes Gardner Denver distributor.

Ted Williams, a salesman for a previous Gardner Denver distributor, showed up at JBS one day in 1990 “It hit me like lightning in the brain. I wonder if JBS would be a good company for Gardner Denver. I put the valve (that he had come to JBS to buy) in my truck, walked up the stairs, and asked to talk to Mr. Bouchard.” … Jack entered into talks with Gardner. After a few meetings, JBS seized the opportunity, signing a distribution agreement and hiring Ted as a compressor salesman. Most of JBS’ existing customers used compressed air to keep their facilities moving. This was the next logical service offering for Bouchard to bring to them.

1991 – Knoxville office opened pump sales & service, soon adding air compressor sales & service.

The expanding endeavors of 1991 also expanded eastward. Bouchard’s success with selling Ingersoll-Dresser Pumps (IDP) in Middle TN, led the manufacturer to award JBS their industrial pump line for distribution in East Tennessee. Experienced JBS salesman, John Horst was sent over from Nashville to get things rolling. The company leased a Knoxville office space and later expanded to a larger facility, enabling in-house pump repair. By June of 1993, Bouchard management convinced an experienced local pump salesman, Gary Bentley, to join Horst’s sales efforts in East Tennessee.

1995 - Key employees departed to start their own, competing fire sprinkler company.

In early 1995, senior JBS employees who Jack had long trusted collected their annual bonus checks and promptly dumped their keys on his desk – a dramatic gesture in their big exit to launch a competing sprinkler enterprise. The prime mover among the gang was the fire sprinkler department head. He next waltzed through the machine shop saying goodbye to potential followers. Jack Bouchard snuffed out this probable route of recruitment. Jack and William Morgan soon hired Paul Satterwhite to keep the department moving. “It was a fun several years trying to get the wheels rolling,” said the now 30-year department head.

1996 – Compressor Division expanded to East Tennessee.

Gardner Denver expanded JBS’ compressor territory into the region. As in Nashville, the Knoxville compressor capabilities piggy-backed on the growing pump sales and service operation. Pump customers such as Willamette Industries (now Domtar) and Eastman Chemical in Kingsport, Kimberly Clark in Louden and TVA’s Kingston plant all had air compresses as well, which provided a natural opportunity.

1998 – Nashville Banner featured “Bouchards still Forging History: Family mixes new science with old iron”.

The article stated: “Today, Bouchard Foundry is the last iron foundry left in the Nashville area and is one of four divisions of John Bouchard & Sons Co.,” wrote Carrington Nelson. She described the operation: “glowing iron flows from the furnace to mold the municipal castings – manhole covers and frames, sewer covers, curb inlets and grates – that are used in construction projects in Tennessee, Alabama, Kentucky and Georgia…In one cycle, Glyndon Mayberry operates the muller, a machine that mixes the sand and clay used in forming molds. Bobby Shoemake—a second-generation employee at the foundry—and Ralph Givens imprint the dark sand with the patterns of manhole covers. Ahmed Adem puts the tops and bottoms of the molds together. Ray Strong and Abdi Roble pour the yellow-hot iron into the molds. (50 of the company’s 165 employees worked in the foundry division)

‘We are the original recycler,’ Miller (foundry manager) says, explaining that the company melts about 25 tons of iron a day recycled from salvage and scrap in the Nashville area. Giant piles of refuse, from old engine blocks to oven burners, get thrown into the mix and eventually emerge as manhole covers and sewer grates. In the past, the foundry even made things as specific as tail sets for walking horses.”

2000 - Over 170 employees celebrated 100th Anniversary.

The Nashville Record, a local business newspaper, published a front-page article about JBS, entitled “Fifth-Generation Company Blends Past and Future for Success.” William Morgan told the reporter: “The greatest strength this company has is its solid foundation, built on the principle that you stand behind your work. You satisfy your customers. Period. We make them happy, even when it hurts us. Our plan is to be invited back. And that philosophy has carried us through 100 years of repeat business.”

William stated: “Our employees are the people who are out in the field with our customers most of the time. Our employees are us. So, whether it’s customers or employees, it’s all about building and maintaining relationships—one at a time.”

2001 - Jack Bouchard appoints son-in-law, William D. Morgan as president.

William Dudley Morgan joined JBS in 1986, after managing projects in Exxon’s Louisiana offshore oil operations and then graduating as valedictorian of his Vanderbilt Owen Business School class. As a fifth generation Nashvillian and a descendant of several business leaders whose paths had crossed closely with Bouchard’s, William’s 1982 marriage to Lisa Bouchard was, in hindsight, providential. From 1986-2001 William had been given systems and departments, balance sheets and butting heads to reconcile. He was more prepared for the presidency than the previous two generations had been.

2003 – Completed large electrical project for Harpeth Valley Utility District and large air compressor project for Y-12 National Security Complex.

In 2003, the first 3 million dollar bid job hit the JBS drafting tables. Andy Maddox, manager of the electrical department at the time, and Don Phelan, its superintendent, led a generator replacement project for the Harpeth Valley Utility District. Andy said. “It was for the entire water plant. We had W. L. Hailey as our underground contractor, and we did miles and miles of conduit and wire underground; tied all the buildings together; put in two huge generators.” Shortly after that Bouchard crews were busy at Y-12 National Security Complex at Oak Ridge, supplying and installing three 1500 HP centrifugal air compressors with corresponding electrical gear, and air dryers.

2004 – Installed fire sprinkler system for Nashville’s Schermerhorn Symphony Center.

Bouchard Fire Protection had its hands full with the unusual, demanding design of what would become one of the premier concert venues in the U.S. “The amazing thing about that building is that it is literally one building in the middle that’s the Symphony hall, there’s an air gap and then another building built all the way around it, which is all of the hallways and bathrooms. It was exactly done for the acoustics,” William Morgan recalled, “So every bit of the piping for HVAC, for the sprinkler, there was a special fitting coming across that air gap so that you would dampen, in theory, the noise that might be on the pipe before it got to that air gap.”

2008 - “The '08 Crisis” financial downturn affected all sectors of the economy.

Bouchard weathered the storm through large jobs, including installing cooling water system at Wolf Creek Dam; piping and equipment installations for Sekisui Plastics in Mount Pleasant, TN and Matheson Tri-Gas’ gas bottling facility in New Johnsonville, TN; mechanical installations for a large medical office building in Dickson, TN; and fire sprinkler jobs for American Constructors at Shelbyville HS, Unionville High School, Vanderbilt University.

2010 – Bouchard crews aided in Nashville Flood recovery.

Emergency pump repairs were completed during the flooding for MetroCenter’s levee pump station, helping to avert the failure of the two-mile levee. Simultaneously, another Bouchard crew helped to prevent flooding in the basement of NewsChannel 5. Richard Eller, the Station Manager of NewsChannel 5 Network recalled, “The water levels were literally inches away from taking the station off the air while we covered this massive weather event live on television. Our first phone call was to Bouchard, to secure pumps and remove the water.” After flood waters receded, JBS crews did extensive flood repair work for the Schermerhorn Symphony Center, AO Smith in Ashland City, Metro Water’s KR Harrington Water Treatment Plant, and many others across Middle TN. Bouchard Fire Protection served as the fire sprinkler contractor for Extreme Home Makeover’s rebuilding of Lighthouse Christian School.

2010 – Mechanical service group expanded to Knoxville, servicing Starbucks and many others.

For decades, the JBS mechanical, plumbing & electrical service group had provided service and repair follow-up work for customers of the construction department. The client base consisted primarily of industrial, municipal and institutional organizations until a relationship began to form with Starbucks Coffee in 2004. The relationship blossomed in the Nashville area around 2007. By 2010, Starbucks asked Bouchard to service Knoxville and Chattanooga area stores, so the service group moved in with the pump & compressor team at the JBS Knoxville office. Since then, JBS has serviced “everything under the roof…and the equipment on top of it too,” performing most any task they need, including HVAC, plumbing, electrical, water filtration, refrigeration, painting, landscaping, and even espresso & coffee machine maintenance. Today, this restaurant equipment and commercial service work extends to 100+ Starbucks stores and 300+ similar customer sites across Middle and East Tennessee.

2013 – Fire Sprinkler system for Vanderbilt University’s Kissam Quad.

Bouchard Fire Protection had been cut down to half its sales from the ‘08 financial crisis, but by 2013 had regained its previous high mark. Early on Paul Satterwhite, department head, says, “Mr. Bouchard told me, ‘we don’t DO schools.’” – a resolve made after a painful overtime-heavy job that still missed deadline. But the sprinkler department found a clutch and figured it out. The Kissam Quad project in 2012-14, proved pivotal. JBS had actually sprinkled the original Kissam Hall way back in 1936.

Through this decade JBS protected many schools with sprinkler systems: Isaac Litton Middle School, TTU, MTSU, four major new-concept dormitories along West End Avenue for Vanderbilt and many others. Regular systems inspections for the overall VU campus became a full-time job for Bouchard sprinkler inspectors. Additionally, Bouchard Fire Protection outfitted: Lifeway’s new headquarters, Seven Springs office and garage buildings, HCA Tri-Star in Columbia, Ramsey Solutions’ headquarters, and the new Tennessee State Museum, among many others.

2015 – John E. Bouchard, III passes; majority owner, Lisa Bouchard Morgan, becomes Chairman.

Jack’s daughter, Lisa Bouchard Morgan became majority owner and Chairman. She remembered what her dad told her out front of the “Bouchard green” brick headquarters one afternoon: “Why would I (have wanted to) do anything else? To carry on what was built before me, keep it going, see what God could do with it, that was a great adventure. You all will probably change the Company’s name.” And just like that he proved himself again a practical, humble steward. Of course the name has not been changed, however.

2018 – Branches opened in Elizabethtown, KY and Evansville, IN, as air compressor sales & service expanded.

After 27 years as a Gardner Denver air compressor distributor in Tennessee, the industry-leading manufacturer expanded Bouchard’s territory across Kentucky and into Southern Indiana. JBS opened brick-and-mortar branch offices in Elizabethtown, KY and Evansville, IN, hiring an experienced staff of local compressed air sales and service experts.

2019 – Awarded $11 million plumbing and HVAC scope for Franklin Water Reclamation Facility Expansion.

Building on the success of large, multi-year mechanical projects for Clarksville’s Wastewater Treatment Plant (Archer Western, General Contractor [GC]), and Harpeth Valley Utility District’s Water Treatment Plant (Brasfield & Gorrie, GC), the JBS mechanical, plumbing, and electrical department took on the HVAC and plumbing scope for the City of Franklin’s Water Reclamation Facility Expansion. Working as a subcontractor for Kiewit Corporation, JBS completed a complex scope, spanning nine separate buildings. Subsequently, JBS was selected for major plumbing and HVAC projects including Metro Nashville’s Central Wastewater Treatment Plant (Brasfield & Gorrie, CMAR), the North Clarksville Water Treatment Plant (Judy Construction, GC), and Metro’s Dry Creek Wastewater Treatment Plant.

2020 – Bouchard employees designated “essential workers” during COVID-19 shutdowns.

Working through the uncertain, early days of the coronavirus spread, the long months of mask mandates and subsequent vaccine controversies, JBS tradesmen soldiered through. Electricians pulled wire into conduit’s for Middle Tennessee industrial facilities, JBS castings were shipped across Kentucky, Tennessee, Alabama and Mississippi, pipefitters’ welding arcs were burning, plumbers hung pipe, Starbucks espresso machines were repaired, millwrights repaired pumps for water plants, technicians maintained air compressors from Chattanooga to Cincinnati, sprinkler fitters installed spray heads in buildings, and accountants tallied nearly 300 jobs per week.

2021 - John Bouchard & Sons Co. becomes certified Woman Business Enterprise (WBE).

The Governor’s Office of Diversity Business Enterprise (GO-DBE) for the State of Tennessee certified JBS as a Woman Business Enterprise (WBE). This, no doubt was quite an unusual shift after 121 years, for John Bouchard & Sons Company to be led by a “son” who is a woman. President, William Morgan was quoted as saying, “Lisa’s increasing involvement over the last decade has prepared us well for the next steps of growth on our horizon.”

2022 – CNC machining added to the Machine Shop’s pump & rotating equipment repair capabilities.

While the machine service department had increased its mechanical stamping press repair and doubled down on its pump and rotating equipment service and repair expertise, the need for CNC machining equipment had become apparent over the years. In 2022, the shop leadership made good on an opportunity to acquire CNC machines and hire experienced personnel.

2025 – John Bouchard & Sons Co. celebrates 125th Anniversary: Building & Sustaining Hardworking Infrastructure Since 1900.

Today, JBS is a 5th-generation, family owned & operated business, headquartered in its founding location near Nashville’s capitol hill, with its foundry operation a few blocks away. JBS branch offices are located in Knoxville, TN, Elizabethtown, KY and Evansville, IN.

Begun in 1900 as a Nashville machine shop, the company incorporated in 1913. Today as a highly-diversified business it serves modern industry through four fully-integrated divisions: The Construction division offers over a century of experience in installation and service of electrical, mechanical, plumbing, and fire protection systems. The Machine Services division provides field service and shop repair for all types of compressors, pumps, stamping presses, blowers, gear boxes and other rotating equipment utilized in the municipal and industrial markets, as well as general and CNC machine work. The Equipment Sales & Service division supplies, services, rents and rebuilds air compressors & dryers as well as pumping, nitrogen generation and vacuum systems, in addition to pipe valves and fittings. The Foundry division provides municipal castings across the Mid-South. JBS manhole covers, trench grates, curb inlets, valve boxes and other foundry products are staples of the region’s infrastructure.