Compressed Air in Manufacturing Processes

In manufacturing, compressed air provides power and functionality to production both directly and indirectly. Here are some common uses.

1) Direct Production Process

Compressed air directly supports key manufacturing processes, such as:

Molding & Forming

Compressed air plays a critical role in shaping materials, providing precision and power during molding and forming processes for the plastics, metalworking, and automotive manufacturing industries.

- Blow Molding: Compressed air is injected into heated plastic preforms or parisons, inflating them against mold walls to create hollow objects like bottles, containers, and automotive parts.

- Pneumatic Forming: High-pressure air drives pneumatic presses or actuators to shape metal sheets or composites into precise forms, widely used in aerospace and appliance production.

- Mold Release and Cooling: After molding, compressed air is applied to eject finished parts from molds and cool them rapidly, enhancing cycle times in injection molding and die-casting operations.

Fermentation & Aeration

In brewing and wastewater treatment (which you don’t want to think of when drinking a beer), compressed air is often used:

- Fermentation: supplying oxygen to microorganisms, promoting their growth and metabolic activity in processes like brewing, biofuel production, and pharmaceutical manufacturing.

- Aeration: injecting air into liquids (e.g., wastewater treatment or fish farming) to raise oxygen levels for microbial breakdown of organic matter or sustaining aquatic life.

Blasting and Finishing

Compressed air is key to blasting and finishing operations:

- Abrasive Blasting: directing high-pressure air mixed with abrasive particles to clean, smooth, or etch surfaces (eg Sandblasting).

- Paint Spraying & Coating: applying coatings in the manufacturing industry. It helps atomize paint, creating an even, smooth finish on products moving along an assembly line.

Packaging

Compressed air is a vital component in packaging operations, enabling speed, precision, and reliability across industries like food and beverage, pharmaceuticals, and consumer goods manufacturing.

- Filling and Sealing: High-pressure air drives pneumatic actuators to dispense liquids, powders, or granules into containers and seal them, streamlining processes in bottling and pouch-filling lines.

- Labeling and Cartoning: Compressed air operates blow-on labeling systems and folding mechanisms, applying labels accurately and assembling cartons efficiently for high-speed production.

- Nitrogen Flushing: Compressed air is converted to nitrogen gas which is then used to fill packages while displacing oxygen. The nitrogen preserves freshness and prevents spoilage in products like snacks, coffee, vegetables and pharmaceuticals. Case Study Here.

2) Process-Adjacent Mechanical Applications

Compressed air is used to facilitate the production process. Many manufacturers prefer air-powered equipment over mechanically powered machinery because it is generally lighter, more durable, and easier to maintain.

Material Handling

Compressed air facilitates efficient, reliable, and precise movement of goods and components across production lines in industries like automotive, electronics, and logistics.

- Pneumatic Conveying: Compressed air transports bulk materials such as powders, granules, or small parts through pipes or tubes, enabling fast and contamination-free delivery to processing stations.

- Lifting and Positioning: Air-powered hoists, grippers, and actuators lift, shift, or position heavy or delicate items, improving ergonomics and precision in assembly or warehousing tasks.

- Pumping Applications: Air Operated Double Diaphragm (AODD) pumps or air-driven liquid pumps transfer fluids, slurries, or viscous materials, offering a safe and efficient solution for chemical or food processing lines and in hazardous applications requiring explosion-proof equipment.

- Sorting and Diverting: Compressed air drives pneumatic diverters and air jets to sort products or redirect them along conveyor systems, optimizing workflow in high-speed production environments.

Actuation and Control

Compressed air delivers precise, reliable power to automated systems across industries like automotive, aerospace, and food processing.

- Pneumatic Actuators: Compressed air drives linear or rotary actuators to move machinery components, such as opening valves or adjusting robotic arms, ensuring accurate positioning in production lines.

- Valve Operation: High-pressure air controls pneumatic valves to regulate the flow of liquids, gases, or materials, maintaining process consistency in chemical or packaging operations.

- Automation Feedback: Compressed air powers sensors and control mechanisms that provide real-time feedback, enabling fine-tuned adjustments in high-precision tasks like assembly or quality inspection.

Heating and Cooling

Compressed air can be used for heating and cooling applications. By directing air into vortex tubes, it is possible to generate large volumes of hot or cold air, which is then used for:

- Cooling overheated equipment to prevent damage and maintain efficiency.

- Heating materials in processes such as drying and curing coatings.

Cleaning and Dust Removal

Compressed air efficiently removes dust, debris, and contaminants from surfaces, tools, and products, ensuring quality and cleanliness in industries like electronics and automotive manufacturing.

- Blow-off and Debris Removal: Using air nozzles, blow guns or air wands, compressed air is used to clear dust, dirt, metal shavings, and other contaminants from surfaces, machinery, and work areas.

- Air Knife Systems: High-velocity air streams remove dust, liquids, and debris from conveyor belts, parts, and packaging in industries like food processing and electronics.

- Filter and Equipment Cleaning: Used to clean HVAC filters, electrical panels, and delicate machinery components where traditional cleaning methods are impractical.

Testing & Quality Control

Compressed air is also used at the conclusion of the manufacturing process through:

- Leak Detection: when components can be pressurized and monitored for pressure drops, ensuring the structural integrity of tanks, pipes, seals and other pressure-tight items.

- Air Gauging: where airflow variations can be used to measure part dimensions with high precision in industries such as aerospace, automotive, machining or other tight-tolerance and critical applications.

Compressed Air for Manufacturing Tools

Compressed air is also widely used in powering pneumatic tools, which are used for assembly, cutting, and drilling. Pneumatic tools are efficient in harsh industrial environments, so using them can decrease downtime and boost productivity. Below are some of the most commonly used compressed air tools in manufacturing.

Pneumatic Drills

Pneumatic drills use compressed air to create precise holes in materials like metal, plastic, and composites. These drills are commonly used in:

- Automotive manufacturing for installing fasteners.

- Metal fabrication for drilling holes in structural components.

- Aerospace industries for assembling aircraft parts.

Unlike electric drills, pneumatic drills offer superior speed, precision, and durability.

Air-Powered Grinders

Air-powered grinders are high-speed rotary tools used for grinding, polishing, and cutting materials. They are commonly found in industries such as:

- Metal fabrication for preparing weld seams and deburring parts.

- Shipbuilding for smoothing surfaces before painting or sealing.

- Automotive repair for removing rust and shaping metal components.

Air Hammers

Air hammers provide powerful impact forces, making them ideal for chiseling, shaping, and cutting materials like metal, stone, and concrete. They are widely used in:

- Construction and demolition for breaking down large materials.

- Metalworking for cutting and shaping sheet metal.

- Sculpting and stone carving for precision material removal.

Air-Powered Saws

Compressed air-powered saws deliver clean, precise cuts in various materials, including wood, metal, and plastic. They are extensively used in:

- Manufacturing for cutting components before assembly.

- Construction for cutting pipes, beams, panels, and other structural components.

- Woodworking for crafting and shaping furniture pieces.

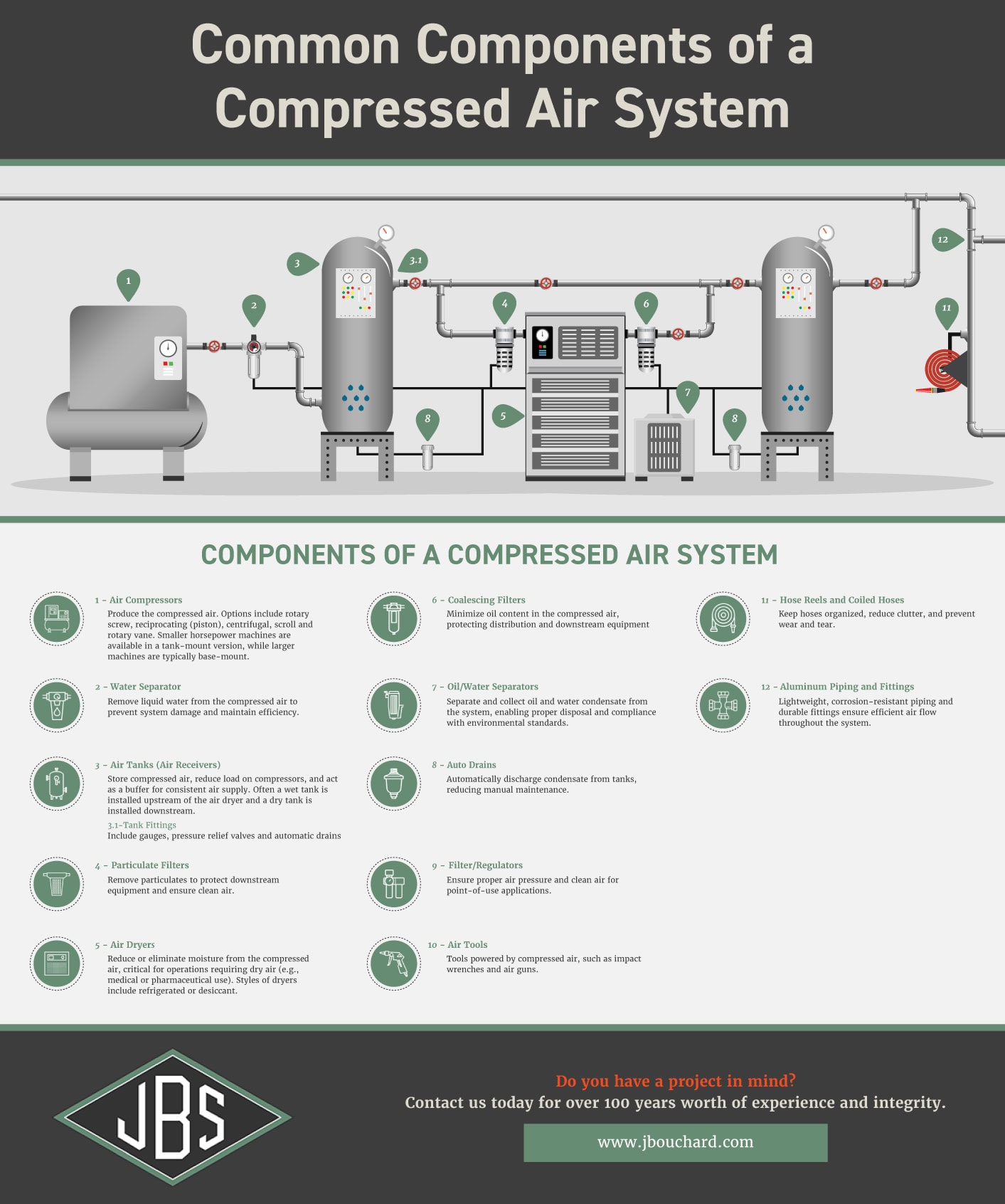

Compressed Air Systems From John Bouchard & Sons

At John Bouchard & Sons, we understand the vital role that compressed air systems play in manufacturing. Our vast experience and expertise in air compressor technology allow us to provide customized solutions that improve efficiency and performance in industrial operations. Whether you need air-powered tools, automation solutions, or a reliable compressed air system, our team is here to help. We provide air compressor products, rentals, and repairs.

To optimize your manufacturing processes with high-quality compressed air systems, contact us today.